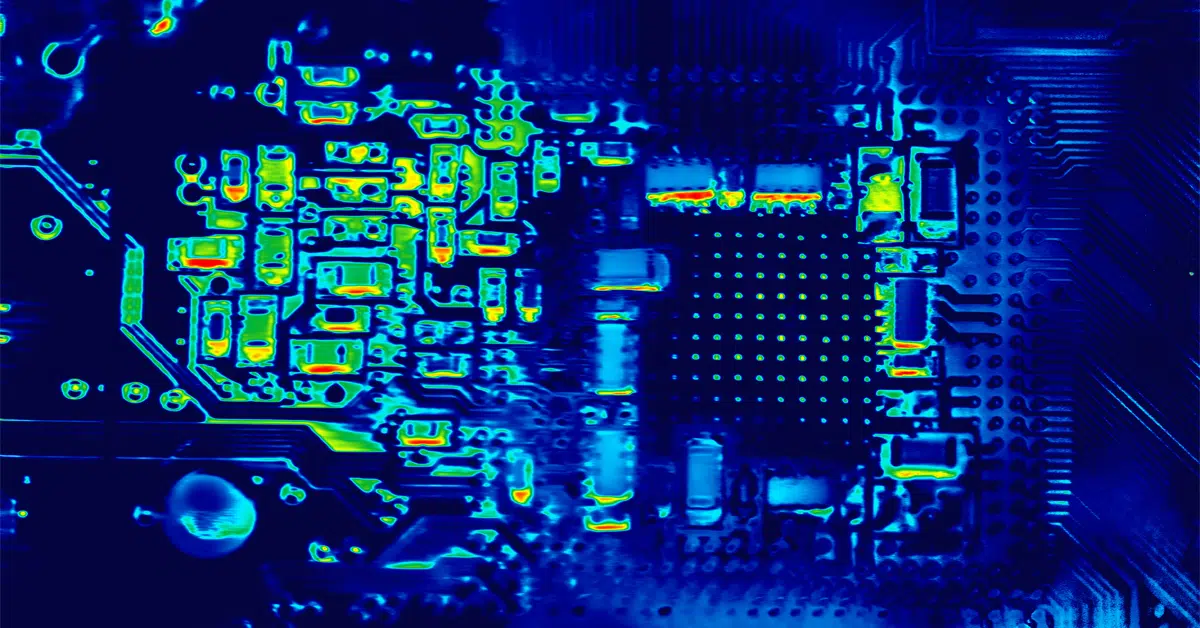

Advancements in Thermal Management for Electronic Enclosures

Effective thermal management is crucial for maintaining the reliability and performance of electronic equipment housed within enclosures. As electronic components continue to shrink in size and increase in power density, managing heat dissipation becomes increasingly challenging. Here, we explore the latest advancements in thermal management technologies that are shaping the design of electronic enclosures.

1. Passive Cooling Solutions

Advancement: Passive cooling techniques leverage natural heat dissipation mechanisms without the use of mechanical components.

Technologies:

- Heat Sinks: Improved designs with increased surface area and enhanced materials for better heat transfer.

- Natural Convection: Enclosure designs that promote natural airflow to dissipate heat effectively.

- Heat Pipes: Efficient heat transfer devices that use phase-change principles to transport heat away from hotspots.

2. Active Cooling Systems

Advancement: Active cooling systems incorporate mechanical components such as fans and pumps to enhance heat dissipation.

Technologies:

- Fan Systems: High-efficiency fans with variable speed controls to optimize airflow and reduce energy consumption.

- Liquid Cooling: Advanced systems using coolant liquids to transfer heat away from components more efficiently than air.

- Thermoelectric Cooling: Peltier devices that provide precise temperature control by leveraging the Peltier effect for heating and cooling.

3. Computational Fluid Dynamics (CFD)

Advancement: CFD simulations enable precise modeling and optimization of airflow and thermal performance within enclosures.

Applications:

- Design Optimization: Predicting temperature distributions and identifying hotspots to optimize placement of components and airflow paths.

- Virtual Testing: Evaluating different cooling strategies and configurations before physical prototyping, reducing development time and costs.

4. Phase Change Materials (PCMs)

Advancement: PCMs absorb and release thermal energy during phase transitions, enhancing thermal management efficiency.

Applications:

- Thermal Storage: Storing excess heat during peak operation and releasing it during low activity periods to maintain stable temperatures.

- Localized Cooling: Placing PCMs strategically within enclosures to manage temperature fluctuations in specific areas.

5. Integration of IoT and Smart Sensors

Advancement: IoT-enabled sensors monitor temperature and humidity levels within enclosures in real-time, enabling proactive management of thermal conditions.

Benefits:

- Remote Monitoring: Monitoring and adjusting cooling systems remotely to optimize performance and energy efficiency.

- Predictive Maintenance: Early detection of potential issues and proactive maintenance to prevent overheating and equipment failures.

6. Advances in Enclosure Design

Advancement: Innovations in enclosure design enhance thermal management capabilities and efficiency.

Features:

- Improved Ventilation: Optimized airflow paths and vent designs to enhance natural convection and cooling efficiency.

- EMI Shielding: Integrating EMI shielding materials that also dissipate heat effectively, reducing the need for additional cooling mechanisms.

Advancements in thermal management technologies are revolutionizing the design of electronic enclosures, enabling more efficient heat dissipation, improved reliability, and extended lifespan of electronic components. By staying informed about these innovations, manufacturers and designers can implement solutions that enhance performance while reducing operational costs and environmental impact.

At Delavari Distributors, we offer a range of electronic enclosures equipped with advanced thermal management solutions to meet the stringent demands of modern electronics. Contact us today to learn more about optimizing thermal management in your electronic systems.